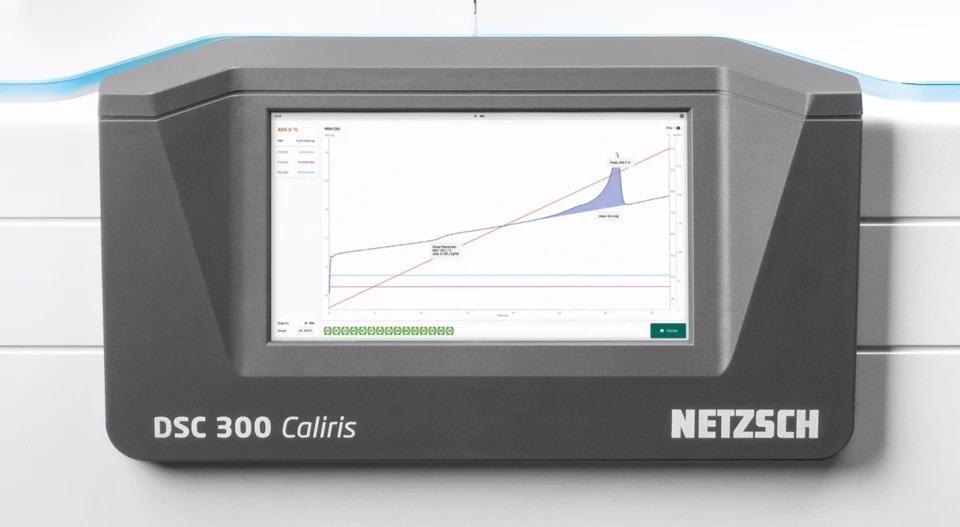

The DSC 300 Caliris® from NETZSCH is the most extensive, reliable and adaptable DSC for material characterization.

Regardless of if users are working in research & development, quality control, contract testing, or the specification of materials for a few applications, information regarding a material’s behavior under varying temperatures and different atmospheres is significant.

The DSC 300 Caliris® supports:

- Material identification

- Quality control

- Phase diagrams

- Compatibility

- Kinetic analysis

- Process optimization

Modular Design — Maximum Flexibility

Ever-accelerating new material developments, triggered by fast-moving mobility and technical trends, require continuous adaptability. The new generation of NETZSCH DSCs is based upon a modular idea.

The DSC 300 Caliris® is the only instrument of its type with exchangeable and interchangeable sensor-furnace modules. The excellent version of the DSC 300 Caliris® enables the exchange of modules, to be able to adapt to present and future requirements.

The DSC 300 Caliris® Supreme — The Future-Proof Choice

This version provides a choice of three modules and could be configured to obtain an unrivaled maximum temperature range of −180 °C to 750 °C. It is possible for users to update their devices anytime to take advantage of the new technological developments or to alter their applications.

The choice of the module utilized remains unlimited. Users can just select between fast heating rates, wide temperature range, or high sensitivity as required.

The DSC 300 Caliris® Select — Tailor Made for Applications

In the DSC 300 Caliris® Select version, there is an initial choice between three presently available modules. The utmost temperature range for the DSC 300 Caliris® Select is −170 °C to 650 °C. The Select version enables the exchange of modules of the same type preventing instrument downtimes.

Both versions are available with an LED status bar and a combined color touch display and can be equipped with an automatic sample changer if desired.

H-Module

Video Credit: NETZSCH-Gerätebau GmbH

High-Performance Module −180 °C to 750 °C

The premium module provides the greatest sensitivity, precision and a very small peak-to-peak noise ratio and impresses with an ideal baseline and excellent reproducibility — the gold standard for the majority of DSC applications.

Jointly with the Supreme version, this module covers the full temperature range from −180 °C to 750 °C. The H-Module is a perfect complement for sophisticated materials research and development in both academia and industry.

P-Module

Video Credit: NETZSCH-Gerätebau GmbH

The Polymer-Module −170 °C to 600 °C

In the field of polymers, this module is ideal for all tasks. Its improved low-mass furnace enables heating rates of up to 500 K/minute over an extensive measurement range. Temperature profiles nearing real processing conditions can be identified.

The measurements can be expedited; thus useful time canbe saved. The P-Module is ideal for research and development or quality control in the polymer processing sector.

S-Module

Video Credit: NETZSCH-Gerätebau GmbH

The Standard Module −170 °C to 600 °C

The routine module integrates high stability and improved resolution of thermal effects. Laser-guided welding processes available for the sensor disks and thermocouple wires provide true robustness and sensitivity.

The monolithic DSC sensor features high optimal resolution and metrological stability. The user-friendly handle S-module is the module of choice for industry and contract laboratories when regular measurements are the primary task.

Keynote – Caliris® Supreme and Select

KEYNOTE: Differential Scanning Calorimeter - DSC 300 Caliris Supreme & Select

Video Credit: NETZSCH-Gerätebau GmbH

Technical Data DSC 300 Caliris®

- The maximum temperature range is from −180 °C to 750 °C

- The maximum heating rate is 0.001 K/minute to 500 K/minute

- Automatic sample changer 192 + 12 positions

DSC 300 Caliris Supreme & Select

Video Credit: NETZSCH-Gerätebau GmbH

- Enthalpy precision (H-Module): ± 0.05% for indium

- Temperature precision (H- and P-Module): ± 0.01 K (standard deviation from the mean value, indium)

- Temperature accuracy (H-Module): ± 0.05 K (Indium)

- Peak-to-peak noise ratio: ± 2 µW

- Repeatability: ± 0.3% (peak area; In, C10H16, Zn)

- Gas atmospheres: Inert, dynamic, oxidizing, and static

Image Credit: NETZSCH-Gerätebau GmbH

Cooling Options

- Compressed air cooling (RT to 650 °C/750 °C)

- Compressed air with switch valve RT to 650 °C/750 °C

- Vortex tube (compressed air): <0 °C to 650 °C/750 °C

- LN2 (−180 °C to 650 °C/750 °C)

- IC40 (−40 °C to 600 °C)

- IC70 (−70 °C to 600 °C)

- IC90 (−90 °C to 600 °C)

Heating/Cooling Rate:

- H-Module: 0.001 K/minute to 200 K/minute

- P-Module: 0.001 K/minute to 500 K/minute

(Maximum rates depend upon end temperature)

- S-Module: 0.001 K/minute to 100 K/minute

Sensor Guide Light. Image Credit: NETZSCH-Gerätebau GmbH

Proteus® Software — The Easy Approach to Users’ Work

Proteus®: Excellent Thermal Analysis Software

The DSC 300 Caliris® functions under Proteus® software on Windows and consists of everything users need to perform a measurement and assess the generated data. The combination of automated routines and intuitive menus makes data interpretation direct, even on sophisticated tasks.

The Proteus® software has been licensed with the help of the instrument but can also be installed on other computer systems.

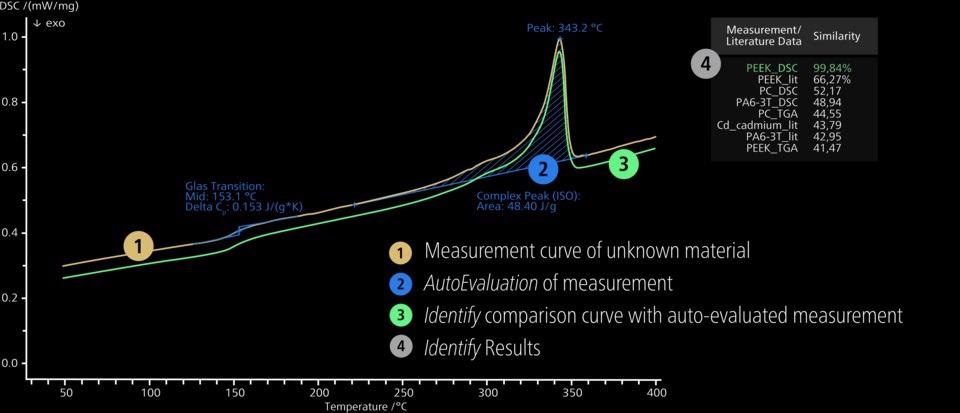

AutoEvaluation

AutoEvaluation is considered an intelligent software enabling the assessment — self-acting or just by pushing a button — of unknown curves. AutoEvaluation examines DSC curves by initially identifying any main effects like melting peaks or glass transitions.

Furthermore, it also interprets the side effects like recrystallization effects in logical steps. Initially, users are provided with access to expert application knowledge in the form of a smart software algorithm.

Identify

Identify is a special software tool utilized for the identification and classification of measurements through database comparison. Besides enabling one-on-one comparisons with separate curves and literature data, it also has the potential to check if a special curve belongs to a specific class. Such classes can include curves of the same material type (material identification) or reference curves for Pass or Fail to test (quality control).

The NETZSCH libraries consist of over 1300 entries connected to various application areas like polymers, pharmaceuticals, inorganics, organics, metals or alloys, and ceramics.

Furthermore, the available KIMW database consists of the DSC curves for one more 1100 commercially available polymer types. Users have the potential to extend Identify as desired, thereby adding unrestricted amounts of their data. Generally, all database entries act as a pool of outcomes and useful measurement conditions.

Image Credit: NETZSCH-Gerätebau GmbH

SmartMode vs ExpertMode

SmartMode has been developed for regular measurements as is common in quality control. It enables quick and simple preparation and the start of measurements, for tasks using clearly defined measurement procedures. Wizards (quick-start routines), user-defined, or pre-defined measurement techniques are useful assistants.

ExpertMode offers numerous possibilities. This mode has been developed for users wanting to access the full scope of Proteus® possibilities. It is ideal for advanced measurement tasks and provides infinite ability.

SmartMode and ExpertMode are considered to be part of the standard configuration of the Proteus® software and can frequently be found next to each other.

Image Credit: NETZSCH-Gerätebau GmbH

Proteus® — My Workspace

When working with Proteus® analysis, it can be overpowering to handle all the functionalities that are available. Users can benefit from Proteus® Workspaces to customize the Proteus® analysis menu and toolbar icons to the daily routine of the users.

It is possible for users to shift all their frequently used items to the front, hide options that are rarely or never in use, and save the preferred setup as their personal workspace. This is beneficial for workstations utilized by more than one person. Users can switch easily between custom and joint workspaces.

Proteus® — Search Engine

Database Capability without the Need to Own a Database License

When functioning with measurement and evaluation data for various materials and from different measurement setups, it is greatly beneficial to be able to filter by certain criteria. The Proteus® Search Engine filters users’ measurement data in just seconds. It is a strong data mining tool. Following selection, previews of measurement curves or analysis status are displayed in an automatic manner.

Folders in the file system could be opened with just the click of a button. Users can make separate searches, for instance, “MyPolymers”, and easily switch between present searches.

Filters can be set by:

- File

- Instrument type

- Sample name

- Evaluated effects

- Peaks

- Onset temperature

- Date of measurement

Image Credit: NETZSCH-Gerätebau GmbH

LabV Primed

LabV Primed — Enter the Digital Lab

The volume of data that has been recorded in analytical laboratories is increasing continuously. In the laboratory of tomorrow, people, devices, and systems will be linked end-to-end.

Keeping track of and organizing collected data to be available for future experiments, final reports or comparison is key for optimized laboratory workflow. Forecasts depending on collected data help enhance quality, part, and process performance, thereby making future laboratories highly efficient.

The NETZSCH DSC 300 Caliris® comes LabV-primed. The LabV cloud solution retains all laboratory data in one place and connects all the devices and systems regardless of manufacturer.

Simple documentation provides more time for tests and interpretation of data to be performed. LabV® links all the analysis techniques, thereby making the processes transparent. Projects are, as a result, more flexible and the product quality is more predictable.

Image Credit: NETZSCH-Gerätebau GmbH

Control Over Users’ Measurements without Logging into the PC

LED Status Bar

The DSC 300 Caliris® offers an LED light bar enabling users to verify the status of their instrument as they walk by, with color adjusted consequently. It is comforting to see from a distance that their measurement is running smoothly and to be able to read instrument status notifications like:

- The instrument is all set

- Measurement is running

- User interaction required

- Measurement is in progress

- Heating or cooling to setpoint

LED Status Bar. Image Credit: NETZSCH-Gerätebau GmbH

Integrated Touch Display

Control Over Measurements without Logging into the PC

The integrated color display enables users to commence a measurement that was earlier made in the NETZSCH Proteus® software. Users can just touch the inclined measurement button on the display and they will be informed regarding the proper setup of the measurement.

This shifts the final check before the commencement of a new measurement instantly onto the instrument. The color touch display enables users to:

- Commence measurements by finger touch

- Follow the measurement progress

- Users can verify the execution list on newly finished measurements

- Get an immediate overview of the assessed measurement outcomes

- Check gases, idle states and the present temperature

- View the progress of users’ measurements and the leftover time remaining

Image Credit: NETZSCH-Gerätebau GmbH