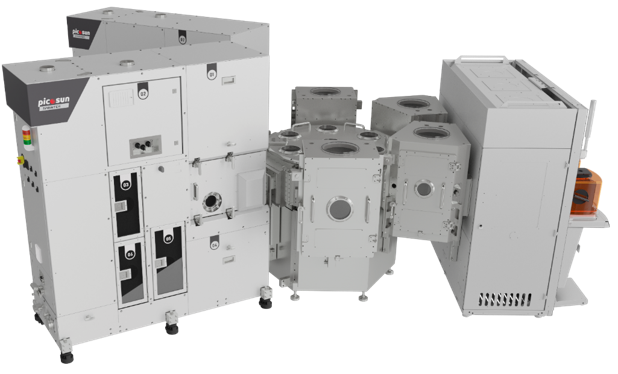

The PICOSUN® Sprinter ALD system is designed to disrupt the batch ALD production on 300-mm wafer manufacturing lines in the semiconductor (for example, capacitor, transistor, and emerging memory), display, and IoT component industries.

In the PICOSUN® Sprinter ALD system, high-k oxide, barrier, and other films are deposited with perfect ALD in large-scale production volumes.

The PICOSUN® Sprinter is completely automated and certified to SEMI S2/S8 standard. It integrates the leading single wafer film uniformity and quality with high throughput, rapid processing, and uncompromising reliability*.

Technical Features and Performance Data

Substrate Size and Type

- 300-mm wafers in batch for high-throughput ALD

- Allows double-side coating

- Samples with high aspect ratio of up to 1:2500

Processing Temperature

Key Features of PicoOS™ Operating System/Process Control Software

- Picosun’s own, proprietary, SEMI-compliant scheduler

- A single common interface to control the entire cluster

- Data is logged for every 20 ms

- Trend data can be easily exported

- Improved recovery features

- EtherCAT-based communication is offered for MFMs and MFCs

- A common event log for the entire cluster

- Recipes can be created or edited any time at the time of system operation

- Freely scalable and configurable recipe editor, no fixed number of steps and loops

- Access rights are available for different user levels

Image Credit: Picosun

Precursors

- Solid, liquid, gas, and ozone

- Level sensors are available for precursor containers

- Constant dispenser for pyrophoric precursors are available as an option (providing up to four tools)

*PICOSUN® Sprinter ALD batch process data on 300-mm Si wafers, Al2O3 process as an example (more data is available on demand):

Source: Picosun

| Parameter |

Value |

| Film thickness 1σ non-uniformity, within-wafer @ 200 °C |

<0.5% |

| Film thickness 1σ non-uniformity, wafer-to-wafer @ 200 °C |

<0.5% |

| Film thickness 1σ non-uniformity, batch-to-batch @ 275 °C |

<0.3% |

| Film thickness 1σ non-uniformity, chip-to-chip @ 275 °C |

<1.0% |

| Cr, Fe, Ni contamination |

<1*1010 at/cm2 |

| Wet etch rate in Al-etch type A solution @ 50 °C |

~ 2 nm/min @ Tdep ≥ 300 °C |

When compared to vertical furnace reactors often used for batch ALD processing, the PICOSUN® Sprinter ALD system offers higher film quality with a lower thermal budget, making it well suited for temperature-sensitive devices as well.

The PICOSUN® Sprinter ALD system also integrates extremely rapid process times with smaller batch sizes compared to vertical furnaces. This enables more production flexibility and also reduces risks without affecting throughput.

The core of the PICOSUN® Sprinter ALD system is the disruptively developed reaction chamber, in which the completely laminar precursor flows guarantee ideal ALD deposition without any parasitic CVD growth. This reduces the requirement for system maintenance.

The PICOSUN® Sprinter ALD module can be incorporated into a manufacturing line or cluster of customers. It is also well suited for individual wafer manufacturing lines since it does not disrupt the process flow. The Sprinter system is run with Picosun’s latest proprietary PicoOS™ operating system and process control software.

The PICOSUN® Sprinter has been made in Finland using European vacuum robotics and process modules.