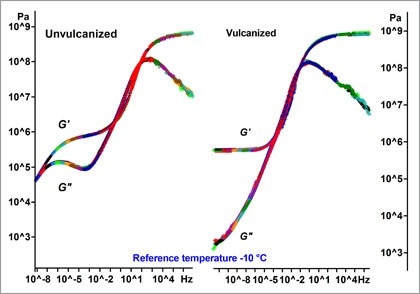

Viscoelastic behavior depends on frequency and temperature, and there is a general equivalence between frequency- and temperature-related behavior during transition processes. This equivalence is referred to as TTS, and it forms the theoretical basis of the master curve technique that enables prediction of polymer relaxation behavior outside the testable range, by which:

- High frequencies are equivalent to low temperature. The sample is in the glassy state and therefore has a high modulus.

- Low frequencies are equivalent to high temperatures. The sample is in the rubbery state and has an accordingly low modulus.

Master Curve Construction

The master curve technique allows the approximately four decades of experimentally accessible frequencies to be extended to about 20. Individual isothermal sweeps are shifted with a mouse click towards a selected reference temperature. Various models have been developed to describe this shift behavior. The computerized combination of these sweeps creates a master curve.

The TTS Webinar

In the webinar, METTLER TOLEDO will explore the Williams–Landel–Ferry (WLF) model used for master curve construction, as well as basic time and temperature equivalence, frequency dependence, and master-curve shift-diagram building using representative applications.